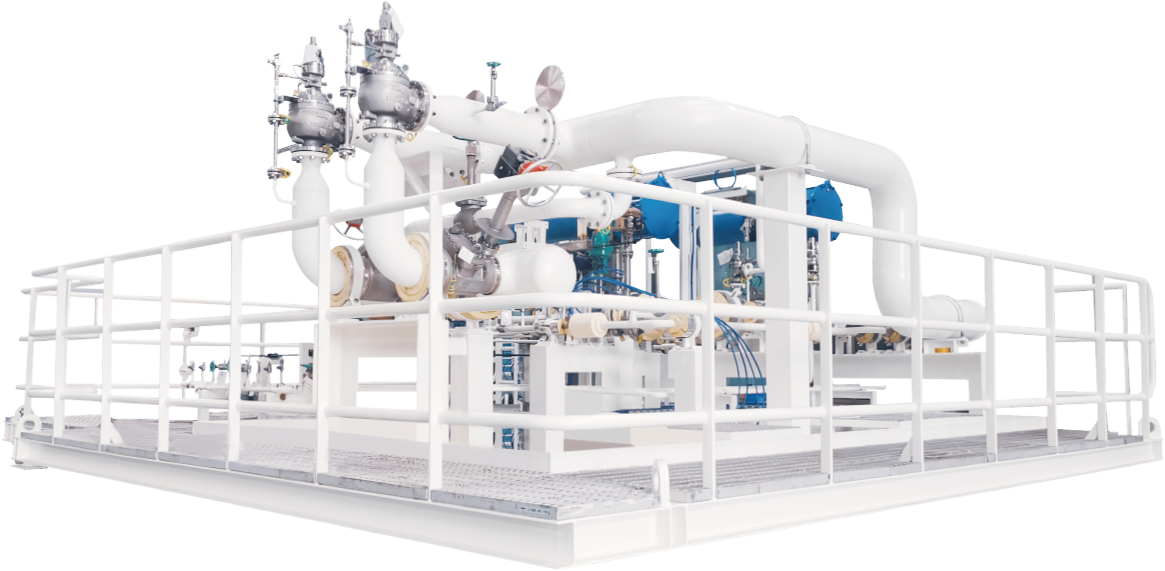

YADA skid production line has an annual output of 350 sets of skids providing one- stop solutions from principle design, detailed design, production design, component manufacturing, pipeline prefabrication and skid integration to installation and commissioning, operation and maintenance services.

Improve R&D and production efficiency through professional design, standardized manufacturing process and experienced production team; Through professional quality controlsystem,inspection equipment and instruments to ensure product quality; Through pipeline prefabrication and skid integration, to reduce on-site installation time, so as to decrease management difficulty, reduce cost and increase efficiency for customers.

100t

100%

traceable350sets

Annual output of skidsWärtsilä, CNOOC

and other wel-known customersboth

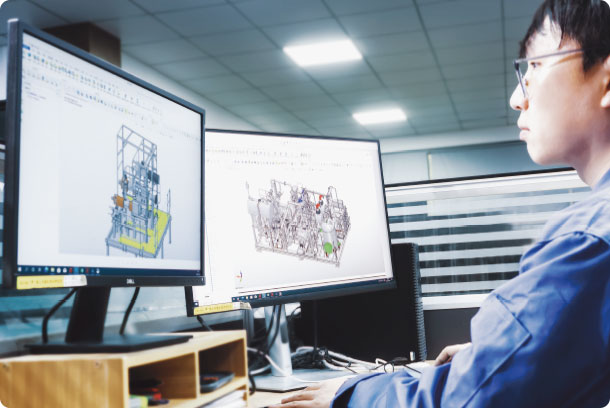

PROFESSIONAL DESIGN TEAM

A professional design team with 100 more engineers, specializing in structure, turbine, pipeline analysis, stress analysis, welding, machinery, automation, etc., can provide pipeline scheme design, modeling design, stress calculation, TDS submission and production design according to customer demand for skid products.

PERFECT WORKMANSHIP STANDARDS

Implement strict requirements and standardized operation guidelines for different functional skids from 100% traceable of each component to standardized key manufacture processes including assembly, welding, Non-Destructive Test, leakage test, final inspection and packaging.

PROFESSIONAL PRODUCT FABRICATION

Pipeline system all homemade, more than 20,000 square meters of skid assembly workshop, experienced production team and rigorous work procedures to ensure the skid product quality.

WHOLE PROCESS QUALITY CONTROL

Professional inspection team equipped with complete inspection equipment and testing instruments execute the whole process of skid quality control from quality planning,ITP review, final inspectionapplication to data submission.

EXPERIENCED PROJECT MANAGEMENT TEAM

YADA has successively served 91,000m3 LPG carriers for Daewoo Heavy Industries, 178,000m' LNG carrier for lMAGl Shipbuilding, 174,000m3 LNG carriers for Hudong Zhonghua Shipbuilding, 119,000 tons of dual-fuel oil tankers for Guangzhou Shipbuilding International, and 14,000TEU dual-fuel container ships for New Yangzi, has accumulated rich project experience.

By defining "Making core" with full chain manufacturing and precision quality,"Service core" as facing the world and providing sincere services, and "Professional core" refers to green development under professional driven, YADA contributes professional strength to promote the low-carbon and green development of global shipbuilding, marine engineering, petrochemical industries and ensures stable pipeline operation for global customers.