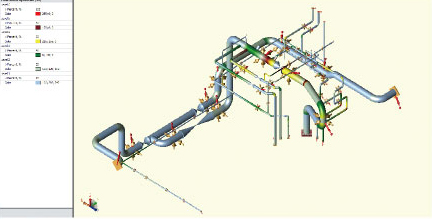

Marine gas filling(vacuum insulation) system, Conveying system, Ventilation system

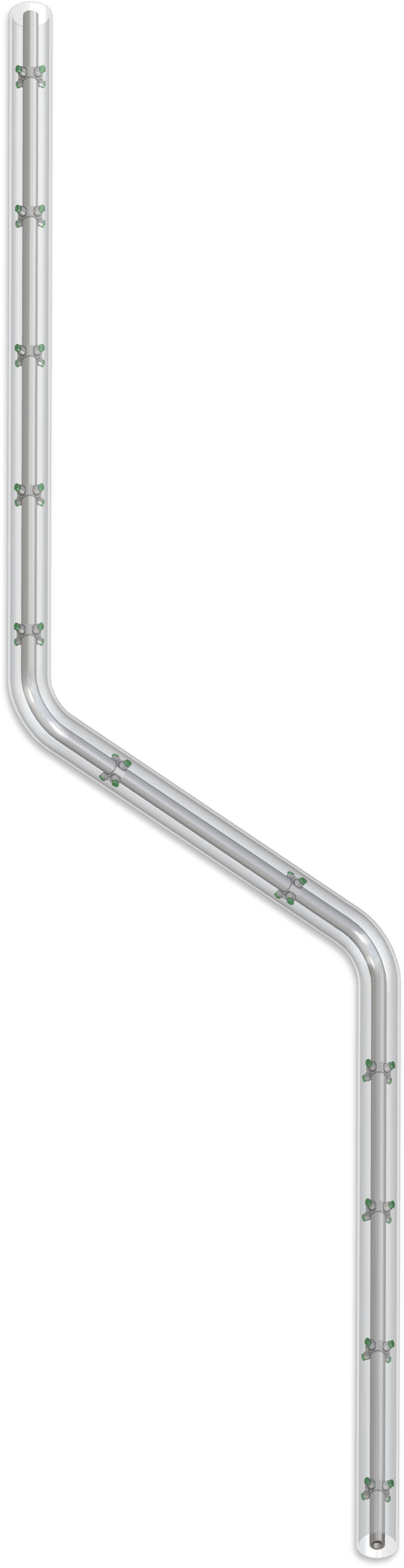

YADA has obtained "continuous vacuum insulation double-wall pipe production and installation process" and other dozens of double-wall pipe related patents, posses complete independent intellectual property rights.

YADA has a large number of professional equipment, can carry out product finite element analysis, fatigue test, hardness test, ventilation test, vacuum test, vacuum life test, 2 million sinusoidal vibration fatigue type test of the self-designed inner pipe flexible support, to prove the designed service life can reach to 40 years.

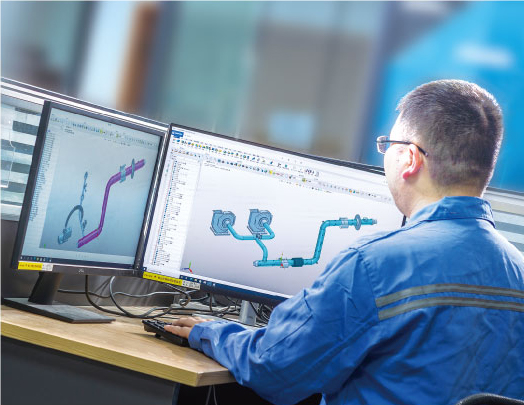

YADA has a professional technical team for P&lD designmodeling design, stress calculation,data submission, production design, process design, etc., its double wall pipe products cover all ship types and class societies

For each type of double wall pipe, from 100% traceable of each component, assembly, welding, Non- Destructive Test, pressure test, passivation, helium detection, packaging and shipping, double wall pipe installation, to vacuum and other key processes all have standard operating procedures.

More than 10,000 square meters of double wall pipe production workshop, independent R&D of double wall pipe specialized precision tooling, professional trained of certified production personnel, rigorous work procedures to ensure the quality of products.

Equipped with spectrometer imported from the United States,PMl detector imported from the United States, Metallographic microscope imported from Japan, Ferrite tester, Ray flaw detector & Eddy current flawdetector imported from Germany & ultrasonic flaw detector, passivation film detector imported from the Netherlands and other professional testing equipment, carry out receiving inspection for all kinds of components and raw materials, manufacture process inspection and key process verification, chemical composition, mechanical performance metallographic structure, cryogenic resistance, corrosion resistance and other quality indicators were tested with 100% full coverage. Professional inspectors control the whole process of product quality from QC planning, ITP review, inspection application to data submission.

A professional installation team over 300 employees with more than 170 projects installation experience, the longest double wall pipe for one ship over 1500 meters, the longest vacuum double wall pipe for one ship over 300 meters.

YADA provides customers with global maintenance services at 27 international ports in 12 countries around the world.

YADA commitment: under the same quality conditions, YADA has an absolute price advantage of double wall pipe, can provide customers with more cost-effective double wall pipe series products.

By defining "Making core" with full chain manufacturing and precision quality,"Service core" as facing the world and providing sincere services, and "Professional core" refers to green development under professional driven, YADA contributes professional strength to promote the low-carbon and green development of global shipbuilding, marine engineering, petrochemical industries and ensures stable pipeline operation for global customers.